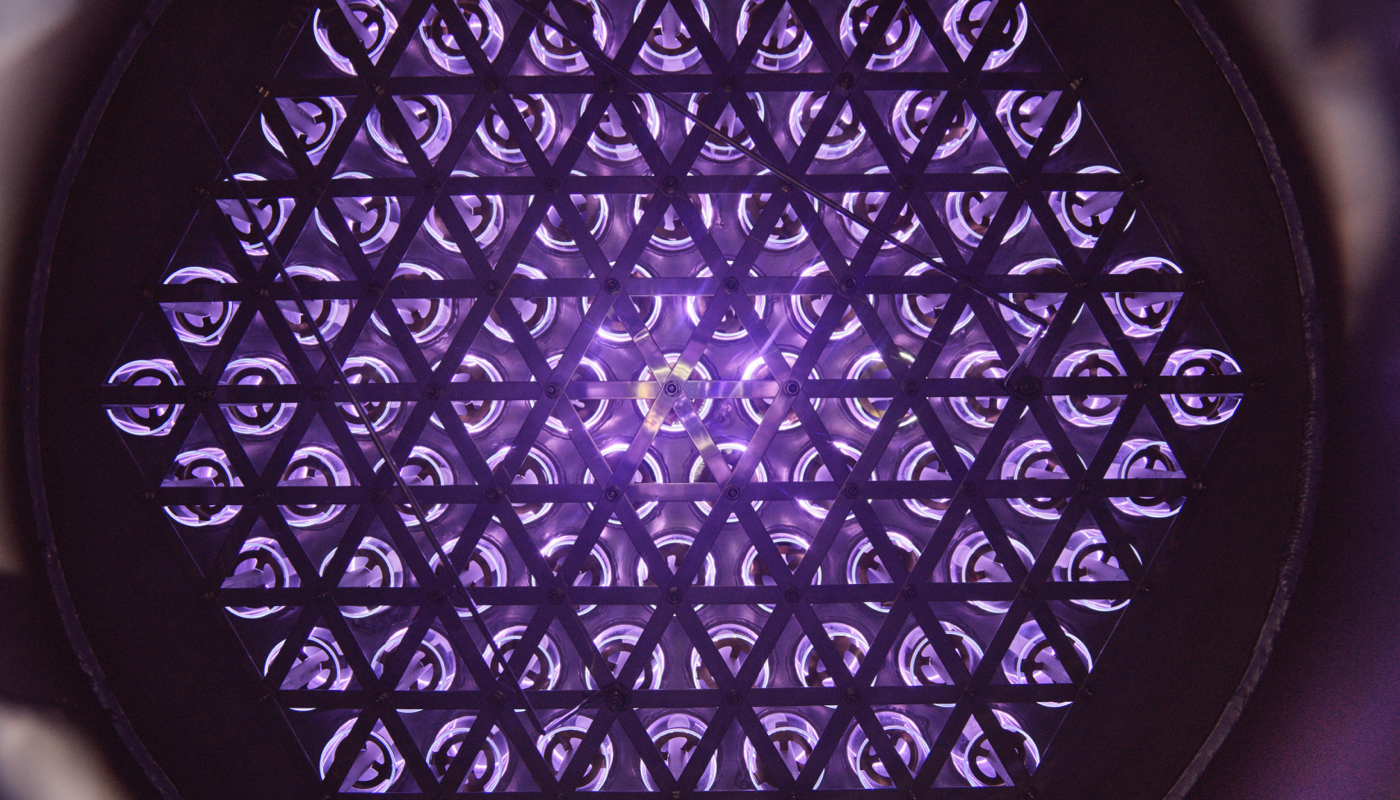

De Nora designs and develops products and technologies that contribute to a sustainable future for the planet. The company’s areas of action range from water filtration and disinfection to the production of electrodes to components and systems to produce green hydrogen through water electrolysis.

Products are not the only sustainable element of the company: De Nora is very attentive to its supply chain and production processes, based on lean manufacturing principles in order to reduce energy and natural resources consumption.

In this article, we’ll discover more about innovation and sustainability of the company.

Enjoy your reading!

WORKING AT DE NORA

WORKING AT DE NORA

Do you want to join De Nora’s team? Click the button and submit your application!

1. Sustainability in the chemical industry: a challenge for the planet’s future

The chemical industry has historically been considered amongst those with the biggest impact on the environment. Extraction and manufacturing of raw materials and the high energy consumption are just some of the challenges to be faced.

The most forward-thinking companies are taking measures to reduce their environmental footprint, optimizing the resources and promoting technological innovation.

De Nora stands out as an institution in the electrochemical sector, because it was able to turn sustainability into a strategic pillar, integrating more and more sustainable practices into its supply chain and production processes.

2. De Nora: innovation and sustainability

For De Nora, sustainability is not simply a goal but a core value, expressed in several ways.

For example, the company has implemented projects aimed at reducing natural resources and energy consumption and is putting into action practices to evaluate the suppliers through thorough ESG questionnaires. Such an approach allows to ensure that every step of the supply chain is in line with the social and environmental sustainability standards.

2.1 Social sustainability

Serving over 100 countries in the world and having a wide range of products, De Nora requires its partners special attention to social and environmental matters, in order to build robust collaborations based on innovation and consideration for sustainability. This is why De Nora is putting its effort into the continuous engagement of suppliers, to support them in their journey for a sustainable development.

The new evaluation process started in 2022 and requires the supplier to fill out a thorough questionnaire about sustainability, developed and managed by CRIBIS. Its aim is to evaluate them through 70 questions divided into five areas: Business, Environment, Social, Governance, Sector.

2.2 Energy sustainability

One of the most innovative aspects has to do with energy supply: De Nora has set the goal to use 100% of renewable energy by 2030, thanks to the installation of photovoltaic plants and the implementation of CAPEX policies, favoring low environmental impact solutions.

2.3 Materials Sustainability

For what concerns materials, De Nora is trying to reduce noble material consumption, crucial in its productive processes. The company has implemented a recycling system that allows the reuse of precious metals and has a 5% recovery target by 2030. Moreover, De Nora is progressively reducing the amount of noble materials used in its products, optimizing the use of resources without compromising their efficiency.

2.4 Supply chain sustainability

De Nora’s attention to the sustainability of its supply chain is constantly growing.

For the new product Dragonfly®, in the hydrogen sector, the company has created an almost entirely local supply chain: 96% of suppliers are located within 80 km from the production plant.

This drastically reduces CO₂ emissions caused by transportation and, at the same time, it has a positive impact on local communities since it opens up new economic opportunities and strengthens the productive fabric of the territory.

2.5 Facility sustainability and lean manufacturing practices

In 2019 De Nora started a Lean Transformation in several production plants, introducing advanced methodologies such as 5S and Total Productive Maintenance (TPM). These policies had a significant positive effect on the organization of the workspace, increasing safety and productive efficiency.

A further innovation is the Shop Floor Management, a structured monitoring system that enables the detection and solution of possible disruptions of productive processes, in real time. Daily meetings between production managers, planning and maintenance departments allow to analyze data and increase operative efficiency.

As a result of these strategies De Nora has achieved important results, such as the Overall Equipment Effectiveness (OEE) increase, from 48% to 97% between 2019 and today, and the significant decrease of machine downtime. Using digital technologies to monitor production has also improved the traceability of processes and consumptions, allowed more efficient use of materials and reduced energy consumption resulting in an enhanced environmental sustainability.

To conclude, De Nora is the proof of the fact that innovation and sustainability can walk along, creating value for the environment and society. The company's initiatives are a role model and highlight that it’s possible to combine industrial growth and environmental responsibility.

LAVORARE IN DE NORA

LAVORARE IN DE NORA